This Winter Project 3D Test Print

The Roof

With the upcoming projects of printing structures like the Chapel in the Pines and an Ancestral Farmhouse I felt it necessary to test the 3D printing of a full structure.

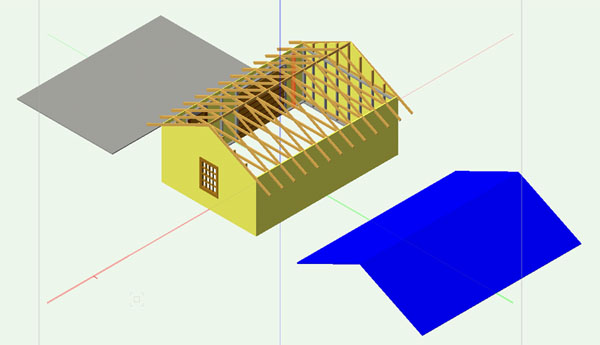

Our Winter Project, which was laser cut and assembled in many scales, provided an example of a 3D structure to test print the structure.

Here is the drawing of the structure in 3 parts. Part one is the floor which does not need to be printed as it may be cut out on the laser. Part two is the structure including the framing, walls and the doors and window, and part three is the roof.

An example of the laser cut construction of the structure is shown in this image.

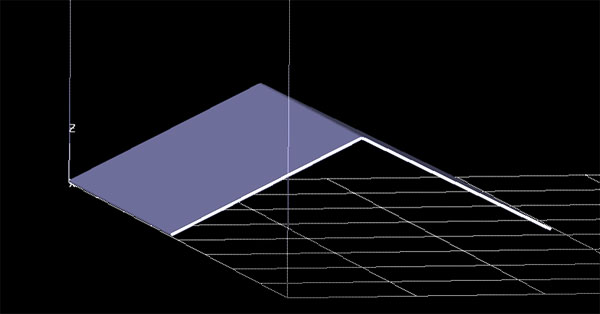

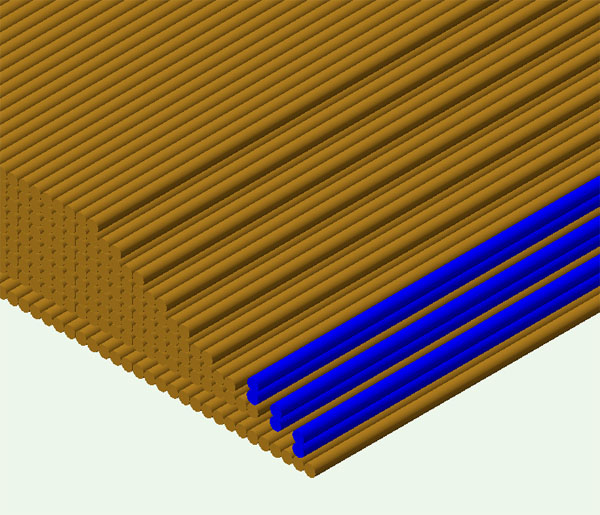

To make the printing easier I separated the .stl files for all 3 elements of the structure. Below is the roof .stl as seen in the Catalyst software used to operate the uPrint Printer in the Fab Lab.

Because there was space in the printer we were able to print the structure and the roof in the same job.

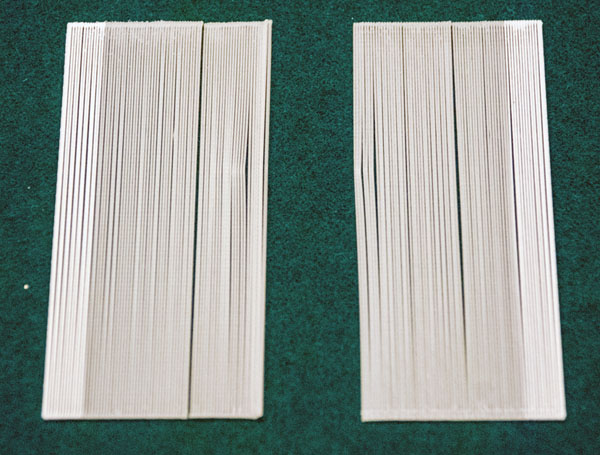

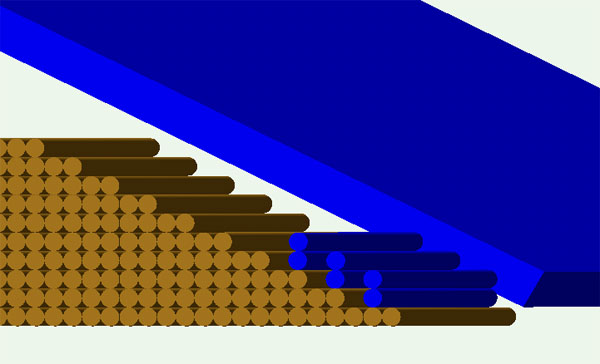

This is the roof structure printing on the uPrint.

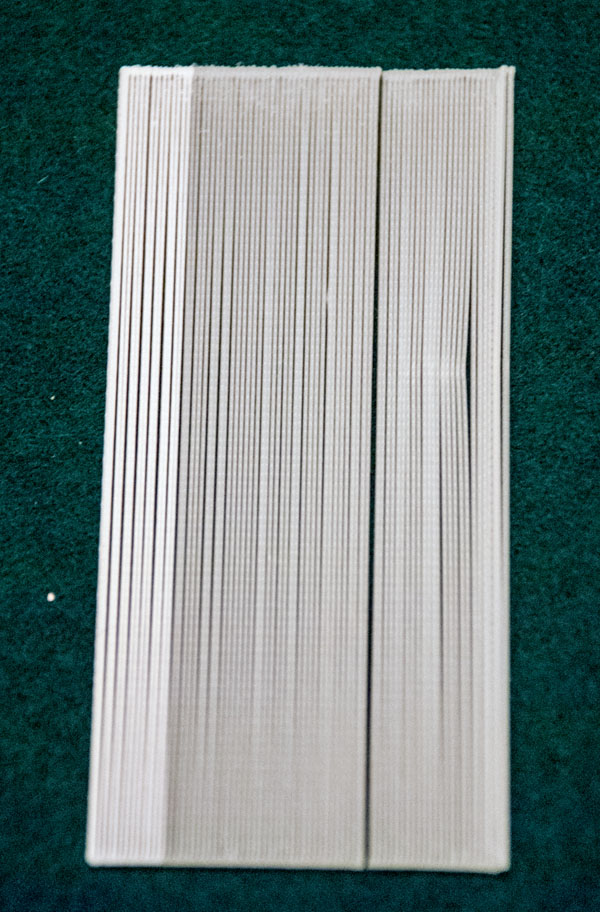

The result of the roof is interesting. After printing and clearing the support material the roof ended up like a fine tooth comb.

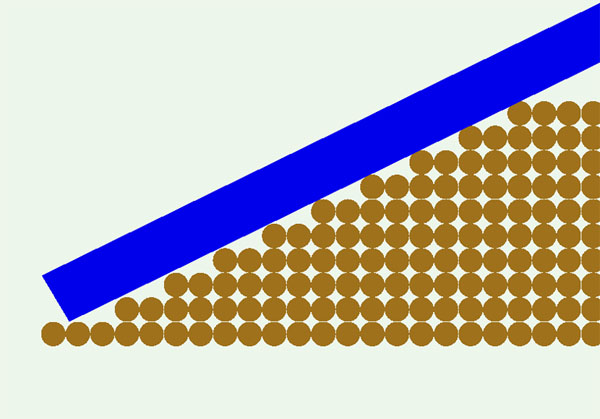

To understand the cause of this I created a drawing of a set of tubes which represent the printer creating .010" plastic to be support for printing the roof of the winter project.

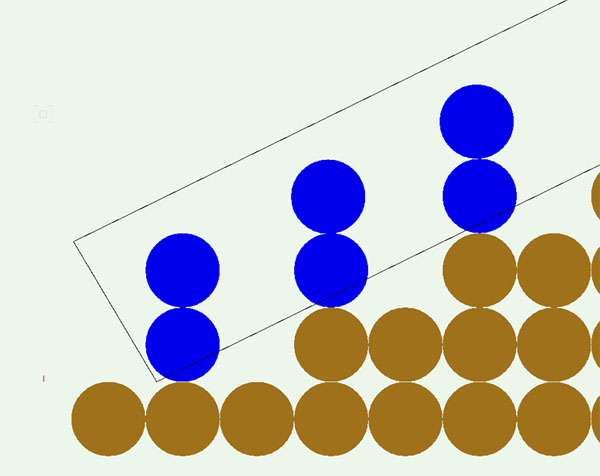

A closer look shows the support material supporting only some of the final roof material to be printed. Blue is printing material Tan is support all at diameter of .010

The angle of the roof has an impact on the spacing of the lines of material available to support the printing of the roof. At 45 degrees every other .010" would be supported however my roof was 26 degrees and the space between supports changed and the roof went from base to peak.

Looking at the placement spaced at the .010" we can see why there would be gaps in the roof (blue) as there is no support.

A close look at the 2X4s in the rafters of the structure shows evenly spaced dots below the 2X4s where the support would be missing. (Click here)

If you have ideas please contact me @ pwussow@gmail.com

Paul Wussow

Updated 8/31/15

Join us in the “Greatest Hobby” as a member of the TLMRC.